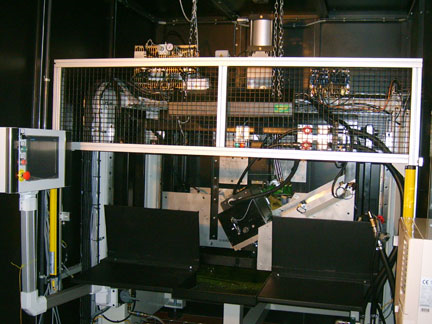

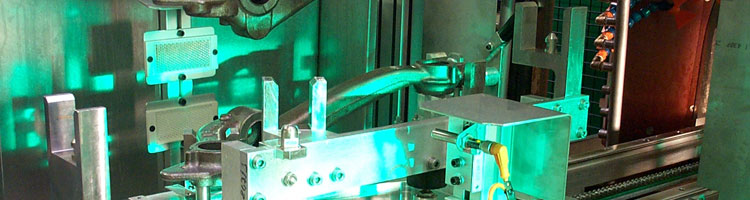

The MPI contactless rotating field is to generate in a multidimensional area, a magnetic flux with variable direction lasting in time. This technique allows to control and to magnetize in one operation the entire part. In industry, on parts with complex geometry, it can significantly reduce the number of magnetization and the handling for number of parts which increases the dutycycles and simplifies the process. MPI contactless by passing current induced improves quality control in releasing some limitations present in the technical magnetization contactless rotating field area. The MPI contactless becomes efficient to forging parts.